Today’s Upward Technology blog post comes from our guest blogger Rick Pay! Rick draws on over 20 years of experience to produce breakthrough results in operations, supply chain strategy, materials and inventory management, and business improvement. He holds a BS in business administration from Colorado State University and an MBA from the University of Montana. Based in Portland, Oregon, Rick serves clients throughout the United States and his work has taken him as far afield as China. He enjoys traveling with his family and is an avid fly fisherman.

The Theory of Constraints is Dangerous

I’ve worked with many companies that found the constraint for delivering value was outside of the system of delivery. For instance, in two contract manufacturers heavily involved with sheet metal, the obvious constraint was the welding cell. The companies worked for years to improve that cell, spending money on robots, work cell redesign and other improvements to reduce cycle time, develop reliable delivery and cut costs. They were understandably frustrated when orders were still late and costs were still too high even after all their efforts.

When we examined the entire value chain – from the suppliers to the customers – we found that the constraints weren’t in the manufacturing process at all. In one case, it was in order preparation, and in the other, in the supply chain.

Innovative thinking, partnerships, and operations discipline can accelerate the delivery of high value to your customers.

Innovative thinking focuses on providing value for the customer and your business. Many of the improvement methodologies mentioned above focus on problem-solving, which looks to the past rather than creating value through future-oriented innovative thinking. Having a strong vision of where you’re going and why brings a sharp focus on creating value and improving the overall system, not just the constraint. Developing a strong business strategy tied closely to operations strategy creates a push-pull performance that can exceed expectations.

What do I mean by push-pull? You might have noticed that many trains now have locomotives in both the front and the back. Pusher engines in the back reduce pressure on the car couplings, which in turn reduces wheel/track friction, significantly improving efficiency. By using the same number of engines, but placing half in front and half in back, the train’s overall performance is improved without expending additional fuel.

In companies, a strong business strategy is a front locomotive and a strong operations strategy brings up the rear. The business strategy sets the company’s vision and direction, while the operations strategy yields innovative supply chain and operations performance, driving profit, delivery, and quality.

Partnerships, both internal and external, are an integral part of an effective operations strategy. In my forthcoming book, 1 + 1 = 100: Achieving Breakthrough Results Through Partnerships, I show how partnerships supercharge performance for companies, their employees, their suppliers, their customers, and the community. By working in partnership, companies can boost quality, delivery and cost reduction, achieving improvements of 10% to 20% and beyond.

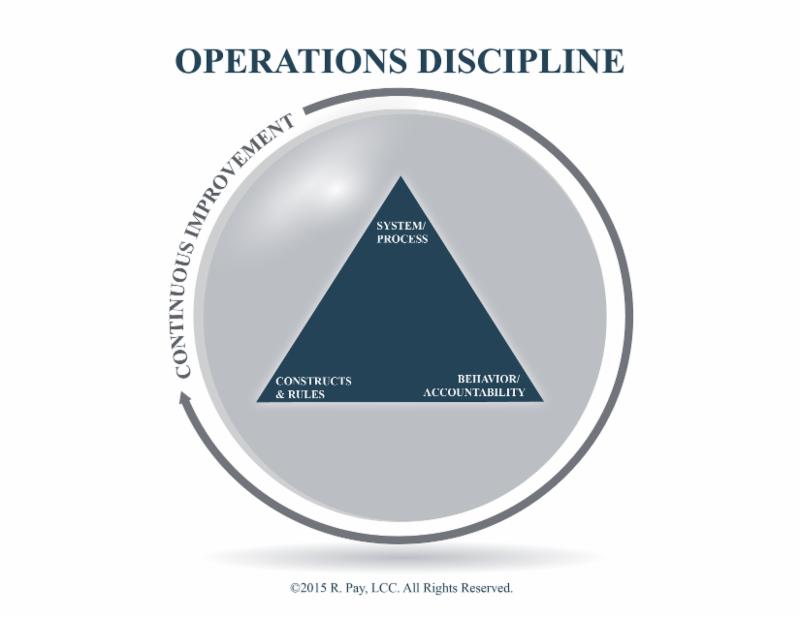

Operations discipline is also critical for success, helping ensure that what needs to get done gets done, in a way that fulfills the company’s vision and provides value to all stakeholders.

I worked with one company whose inability to properly launch a job into production caused several post-production issues such as large payment hold-backs, unplanned failure work, profit erosion, and customer relationship deterioration. By developing strong project initiation processes, assigning accountability and ensuring proper execution, the company dramatically improved profit, cash flow, and customer satisfaction.

A big thank you to Rick for letting us reblog. If you’d like to hear more about the great people we work with like Rick, and how Upward Technology can help your company innovative in its thinking and technology contact us today!

Leave A Comment